Redefining American Semiconductor Manufacturing

Hudson Hi-Tech is establishing America’s newest semiconductor foundry in New York, committed to delivering all your semiconductor manufacturing needs with precision and reliability. Powering AI, autonomous vehicles, defense systems, and 5G infrastructure, we bring over 20 years of specialized metallurgy expertise to every project. Founded by industry veterans, we view manufacturing not just as science, but as art—a regional partner you can trust for advanced semiconductor solutions.

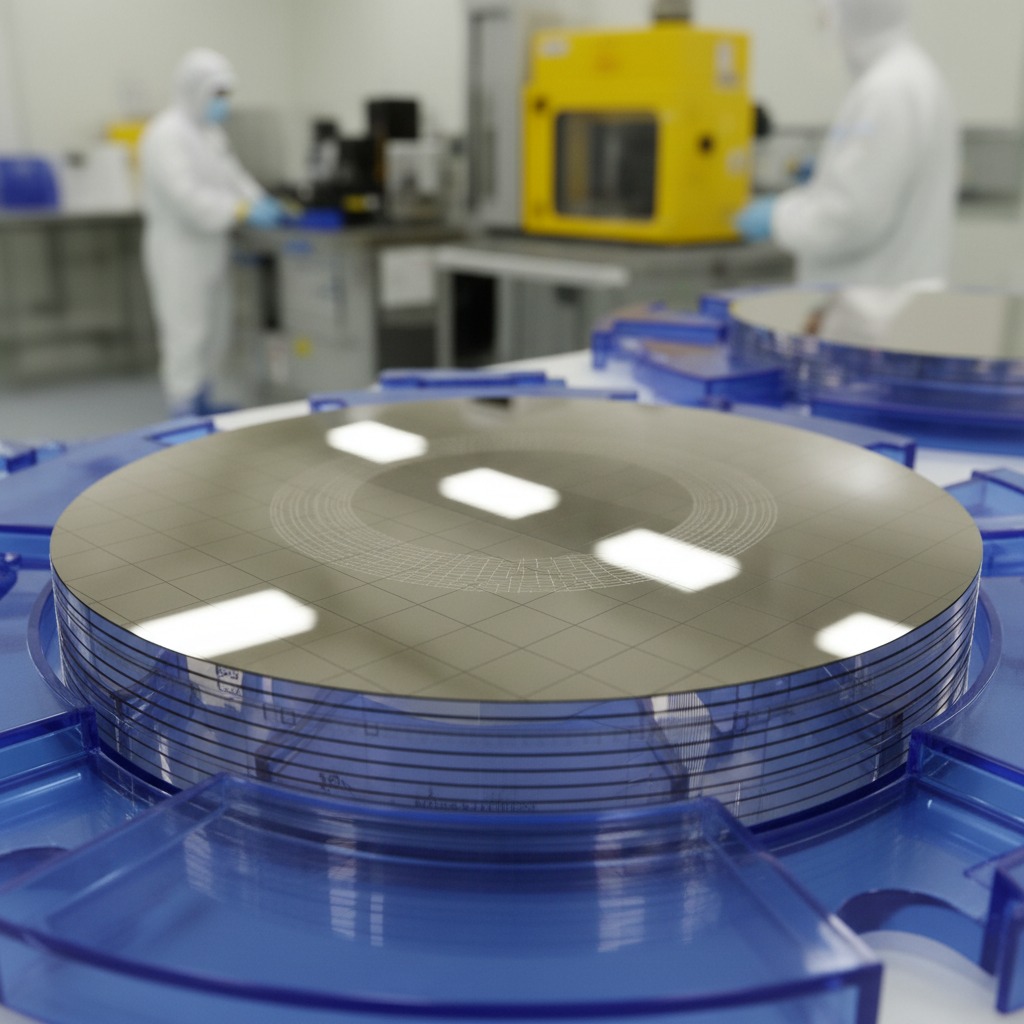

At the heart of our operation is the classic Czochralski (CZ) method, a proven technique for producing semiconductor-grade silicon ingots with exceptional purity levels—backed by meticulous attention to your precision needs at every stage. Through inland manufacturing and local sourcing, we deliver supply chain resilience and reduced lead times for domestic industries. Silicon features four valence electrons and crystallizes in a diamond cubic structure, creating the strong mechanical properties and atomic lattice precision essential for advanced semiconductor applications. Our multi-diamond wire cutting technology ensures consistent wafer thickness and optimal surface quality, while our lapping processes deliver exact specifications for photolithography and circuit deposition, achieving total accuracy from atomic structure to final product for local production and usage.

Hudson Hi-Tech manufactures hyper-pure semiconductor-grade silicon ingots with 99.9999% purity, transforming them into flawless wafers through advanced diamond wire cutting, custom grinding, and mirror-finish polishing processes.

Classic Czochralski method producing semiconductor-grade materials with 99.9999% purity.

High-quality semiconductor wafers with consistent thickness and exceptional uniformity for advanced applications.

Tailored specifications meeting exacting standards for photolithography and circuit deposition.

Our competitive edge goes beyond location. With state-of-the-art pullers, precision diamond wire cutting, and custom grinding processes, we deliver wafers that meet frontier technology standards while maintaining cost efficiency through economies of scale. We also maintain a tightly integrated quality loop that links material sourcing, growth, slicing, and finishing into one continuous flow. This lets us scale output without ever compromising on consistency.

Cut foreign dependency and supply chain risk

Expansion plans to 5M wafers monthly

NY’s chip corridor enabling faster growth

20+ years of specialized crystal pulling experience

U.S. Government-Backed Initiative

Regional partner driving industry growth

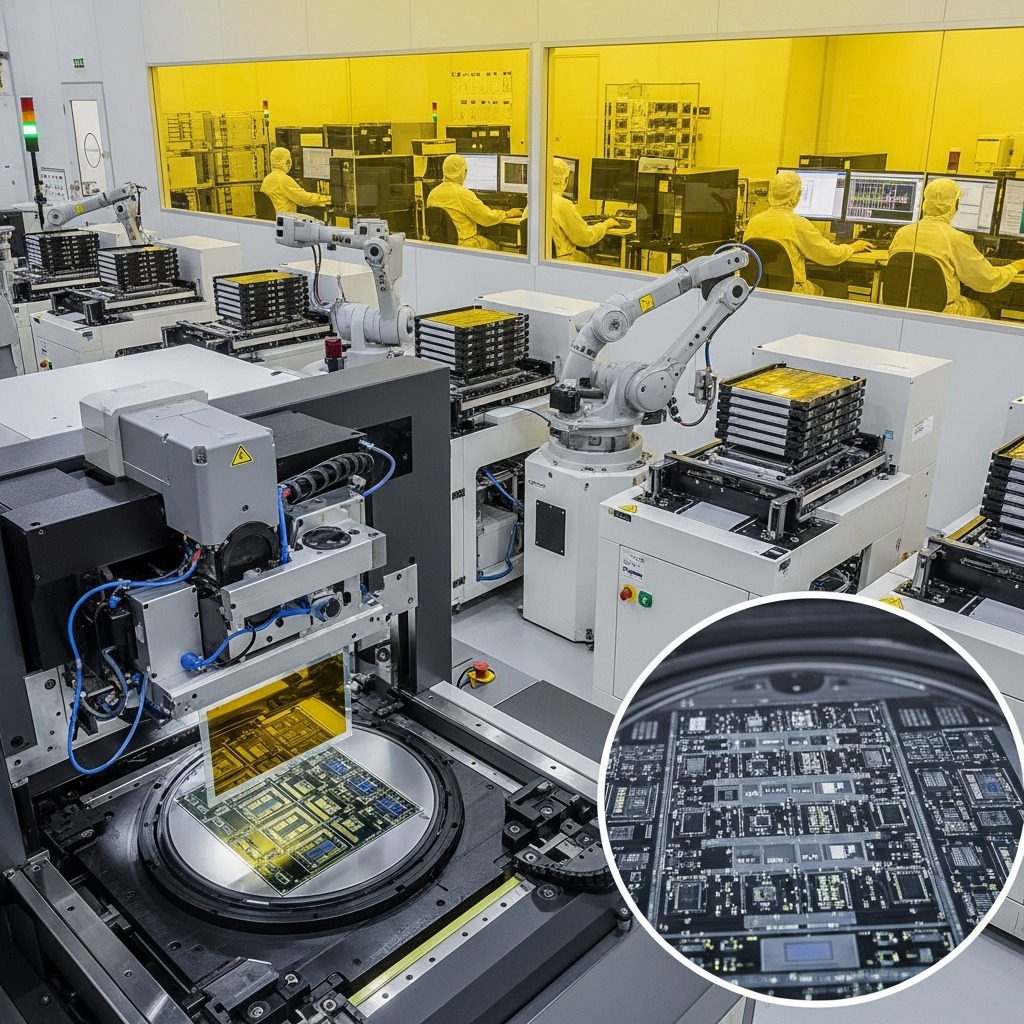

Our wafers accelerate innovation in electronics, optoelectronics, and power-device manufacturing. These next-line users form the backbone of semiconductor growth and play a pivotal role in expanding high-value market opportunities.

Building the Core Elements of Electrical Control

They produce fundamental components—transistors, diodes, rectifiers, and high-voltage power devices—that drive everything from consumer electronics to industrial systems. Our wafers deliver the precision and stability required for consistent electrical performance. This enables manufacturers to achieve higher efficiency, lower losses, and improved reliability across power applications.

High-Frequency and High-Power Device Innovators

This segment develops advanced MOSFETs, FETs, and HEMTs used in RF communication, high-speed switching, and next-generation power systems. Our wafers provide the uniformity and material integrity essential for high-frequency stability. These qualities help device makers push boundaries in performance, thermal handling, and power density.

Designers of Intelligent and High-Density Chip Systems

From processors and memory units to mixed-signal and logic ICs, these manufacturers create the computing backbone of modern technology. Our wafers support fine patterning, high circuit density, and consistent electrical characteristics. This ensures dependable performance for complex chip architectures across diverse applications.

Enabling Light-Driven and Optical Technologies

LEDs, laser diodes, and photonic sensors all rely on high-purity wafer substrates to deliver optical accuracy and efficiency. Our wafers ensure stable light emission, precise signal detection, and long-term reliability. These qualities help manufacturers build advanced lighting, communication, and imaging solutions.

20123 81866

andreww772@yahoo.com

New York