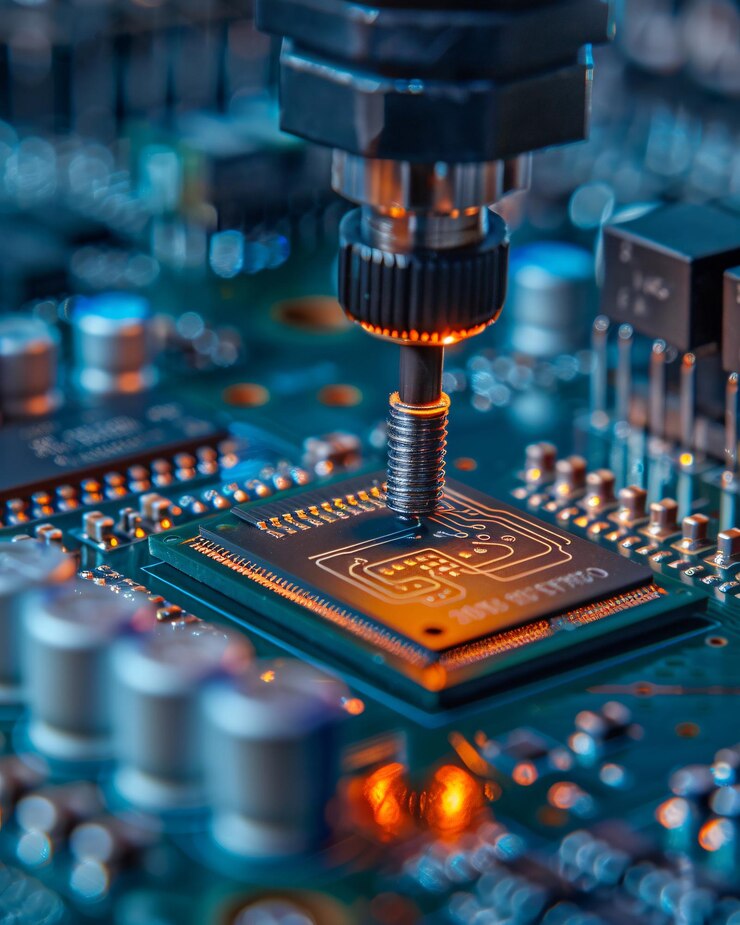

The Problem

The global semiconductor market is projected to exceed $1 trillion by 2030, yet only 31 foundries serve 5.5 billion end-users worldwide. The U.S. produces just 10% of semiconductors despite massive domestic demand, creating critical supply chain vulnerabilities that have cost industries billions in losses. The 2021 chip shortage alone resulted in $210 billion in automotive losses and 12-15% production drops across consumer electronics.