Our product line is built to power the next era of electronics manufacturing—right here in New York. From ultra-pure monocrystalline silicon wafers to wide-bandgap materials like SiC and GaN, we supply the essential building blocks for high-performance chips, power devices, and frontier research.

High-purity, precision-engineered monocrystalline silicon wafers manufactured to meet stringent cleanroom and semiconductor fabrication standards. These wafers offer exceptional uniformity, low defect density, and excellent thermal stability—ideal for ICs, sensors, MEMS, and advanced electronic devices.

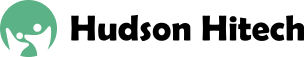

High-Voltage, High-Efficiency Material for Power Devices

Our SiC wafers support high-temperature, high-voltage, and high-efficiency power device applications. They deliver exceptional thermal conductivity and switching performance crucial for EVs, energy systems, and industrial power electronics. As global demand for power semiconductors grows, SiC remains one of the most future-ready materials.

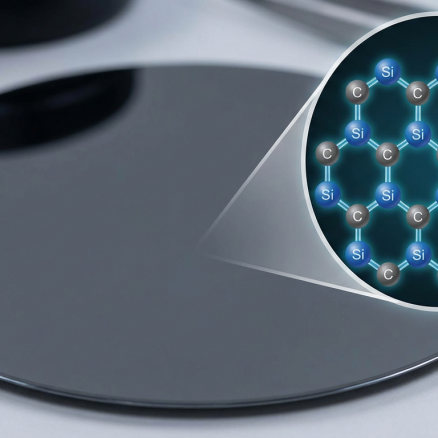

High-Purity Substrates for Infrared, Optoelectronic & Power Applications

Germanium wafers provide exceptional carrier mobility and infrared transparency, making them ideal for high-performance photodetectors, solar cells, and advanced optoelectronic devices. Their uniform crystalline structure ensures superior signal sensitivity and efficient energy capture, supporting next-generation sensing and communication technologies.

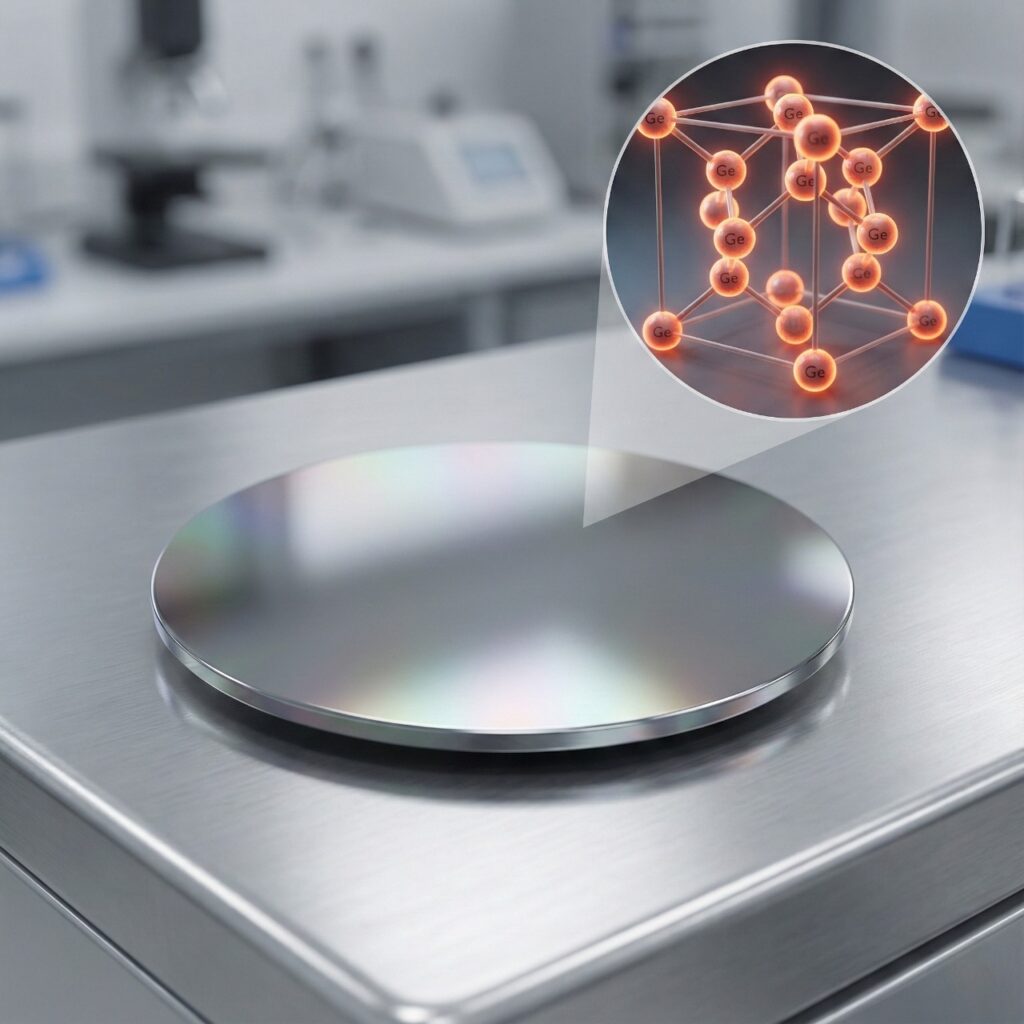

Wide-Bandgap Platform for Fast, Compact Power Systems

Our GaN substrates enable ultra-fast, high-efficiency power conversion in compact form factors. They are engineered for RF systems, power electronics, fast chargers, and communication hardware. With rising demand for energy-efficient electronics, GaN continues to outperform traditional silicon in performance-per-watt.

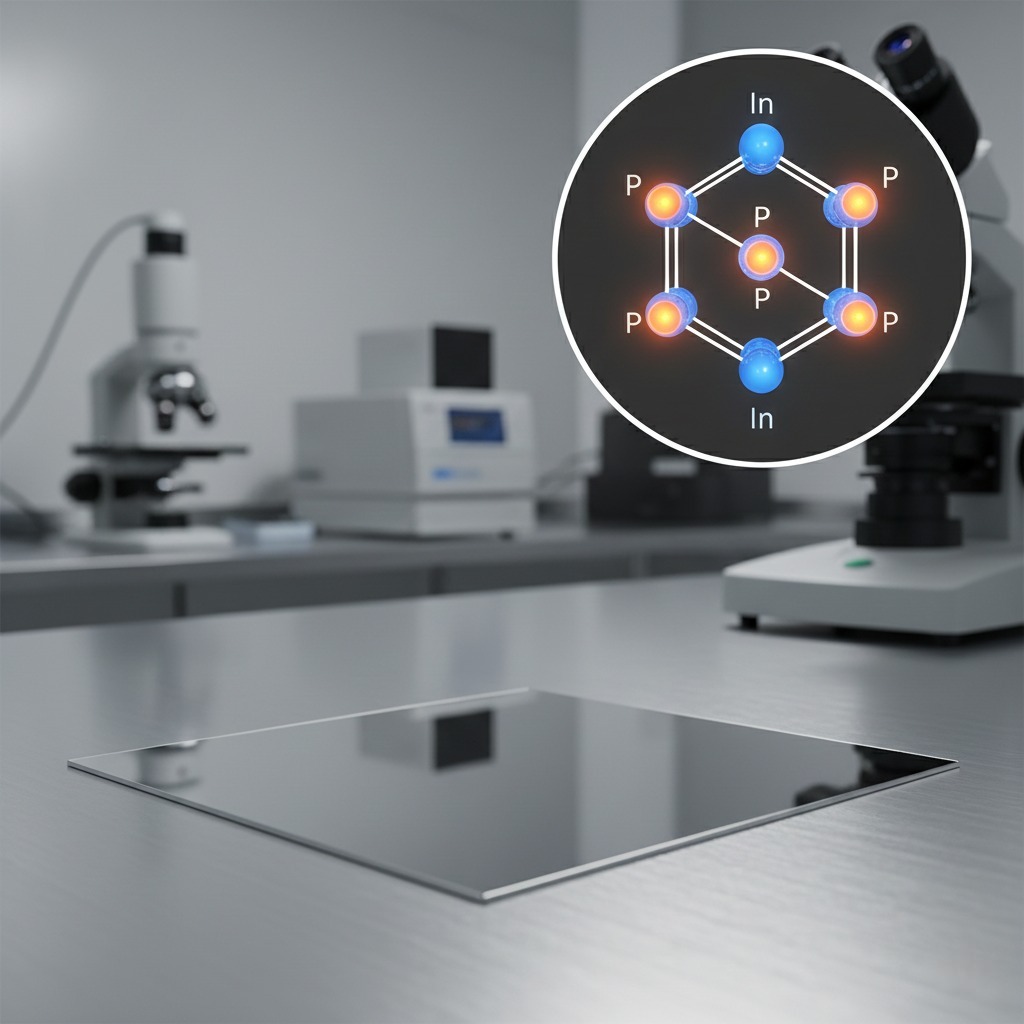

Premium III-V Substrates for High-Speed Photonics & Telecom Devices

Indium Phosphide wafers are engineered for ultra-high-frequency electronic and photonic applications, including 5G/6G systems, high-speed lasers, and quantum communication hardware. With excellent electron mobility and direct bandgap properties, they enable low-loss transmission, efficient light emission, and exceptional performance in cutting-edge optoelectronic components.

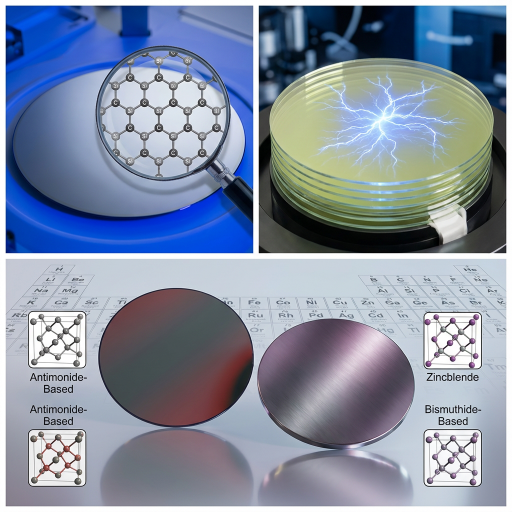

Specialized III–V Materials for Infrared & High-Mobility Applications

These advanced compounds are ideal for infrared sensors, photonics, and high-mobility semiconductor devices. They offer unique bandgap properties that unlock performance in extreme or niche environments. Their adoption is steadily expanding in aerospace, defense, and precision optical systems.

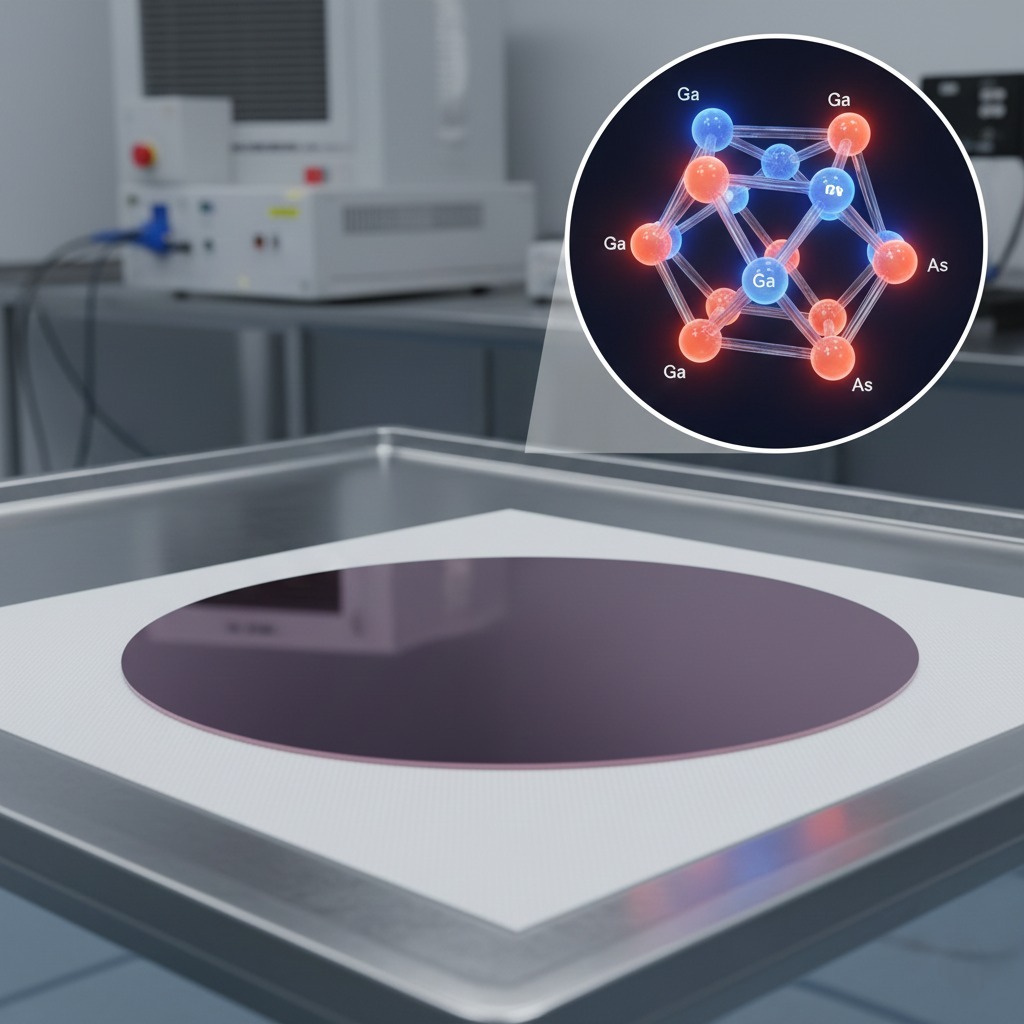

Ultra-High Mobility Substrates for RF, Aerospace & High-Efficiency Solar

GaAs wafers deliver superior electron mobility and high-temperature stability, making them ideal for RF amplifiers, satellite communication systems, and multi-junction solar cells. Their direct bandgap and low noise characteristics support high-power, high-frequency performance needed in advanced aerospace, defense, and energy-efficient electronic technologies.

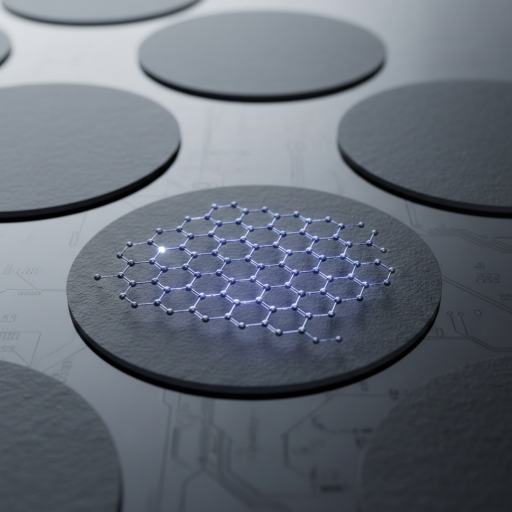

Ultra-High Mobility Platform for Next-Generation Nanoelectronics

Our graphene materials deliver exceptional electrical mobility, mechanical strength, and thermal performance. They are suited for nano-electronics, sensors, advanced composites, and transparent conductive devices. As research accelerates, graphene remains a key enabler for next-generation high-speed and flexible electronics.

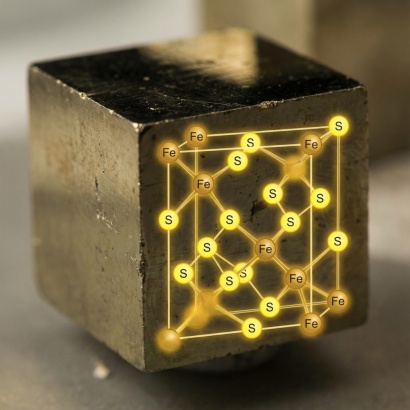

Sustainable Semiconductor Material for Emerging Green Technologies

Pyrite wafers provide a cost-effective, earth-abundant platform for sustainable semiconductor applications. Their optical absorption and material availability make them promising for photovoltaics and experimental electronics. With rising interest in green tech, pyrite continues to draw attention for scalable clean-energy devices.

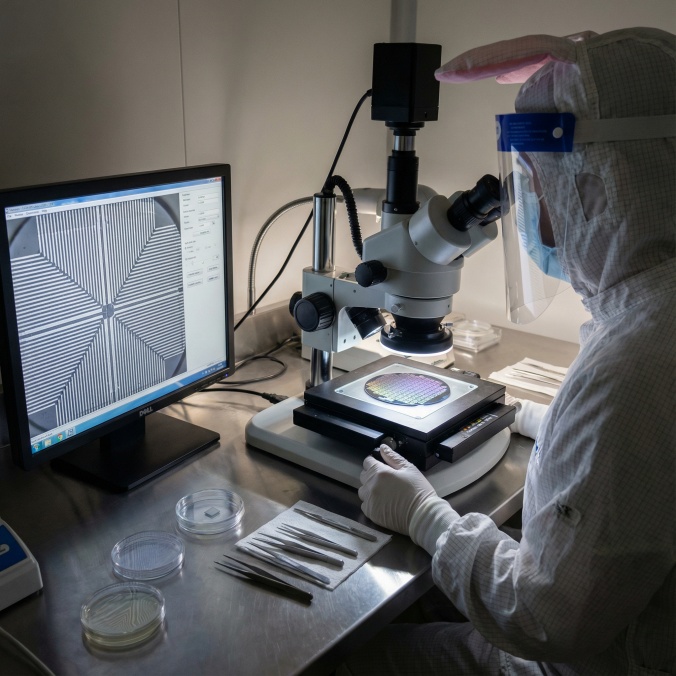

Our technical and manufacturing services are designed to support end-to-end wafer processing with precision, consistency, and scalability. Each process strengthens material quality and prepares wafers for high-performance semiconductor applications.

Acid Coating & Dipping for Defect-Free Wafer Surfaces

Our surface-treatment processes—combining precision acid coating and controlled dipping—prepare wafers for high-yield fabrication. These treatments ensure uniform cleaning, controlled etching, and enhanced surface adhesion for subsequent process layers. This step is essential for reducing defects, improving consistency, and achieving stable downstream device performance.

Deposition Techniques for Consistent Thin-Film Layering

We use advanced deposition methods to form ultra-uniform thin films essential for device architecture. These controlled layers enable electrical, optical, and structural performance required in semiconductor manufacturing. With high repeatability and precision, our deposition services support scalable production across multiple device types.

Compounding & Doping for Customized Material Properties

Through specialized compounding and atomic-level doping, we tailor material compositions to meet precise electrical and performance specifications. These processes modify conductivity, carrier concentration, and other critical parameters required for advanced semiconductor applications. The result is engineered material behavior optimized for both high-performance and emerging device technologies.

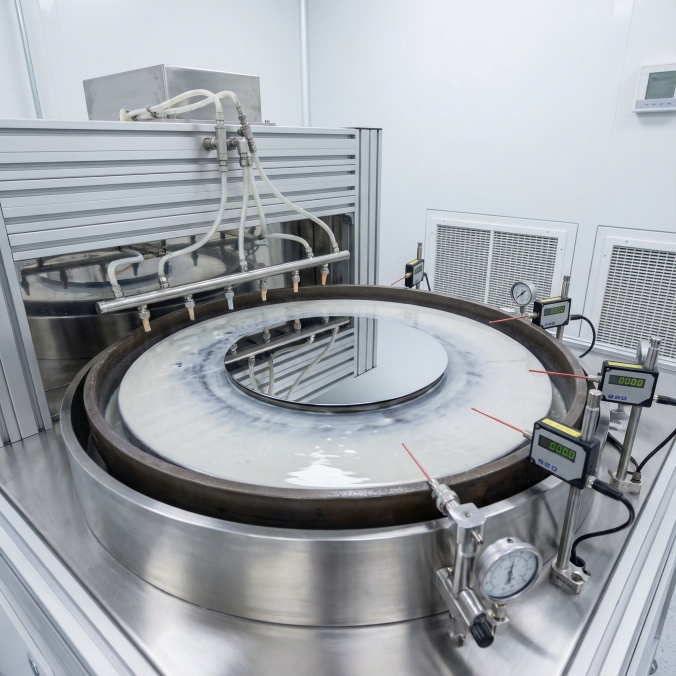

High-Accuracy Surface Planarization for Wafer Uniformity

Our precision lapping service delivers exceptionally flat, smooth wafer surfaces essential for tight-tolerance manufacturing. By removing micro-level variations, lapping enhances structural stability and prepares wafers for further polishing or deposition steps. This ensures consistent device fabrication with improved efficiency and long-term reliability.

From AI to aerospace, our precision silicon wafers are the foundation of breakthrough innovations across critical industries. Every Tesla autonomous vehicle, NVIDIA AI accelerator, and defense-grade communication system starts with the hyper-pure substrates manufactured in our New York facility.

Mission-critical semiconductor components for radar systems, satellite communications, guidance systems, and defense electronics.

High-frequency substrates enabling 5G infrastructure, base stations, network equipment, and communications backbone connectivity.

Precision substrates for diagnostic equipment, medical imaging systems, patient monitoring, and implantable electronic devices.

Photovoltaic-grade silicon supporting solar cell manufacturing, renewable energy conversion, and sustainable power solutions.

Sensor arrays, smart home devices, industrial IoT systems, and connected infrastructure transforming modern living and working.

High-performance substrates for server processors, memory chips, storage systems, and data center infrastructure powering cloud.

20123 81866

andreww772@yahoo.com

New York